With the continuous strengthening of environmental awareness and the increasingly prominent global energy crisis, biomass fuel pellets, as an environmentally friendly and low-carbon alternative fuel, have broad market prospects. Many friends are interested in learning about the biomass pellet production line project. For pressing pellets, raw materials play a vital role. Today, we will learn more about the raw materials.

What are the raw materials for biomass pellets?

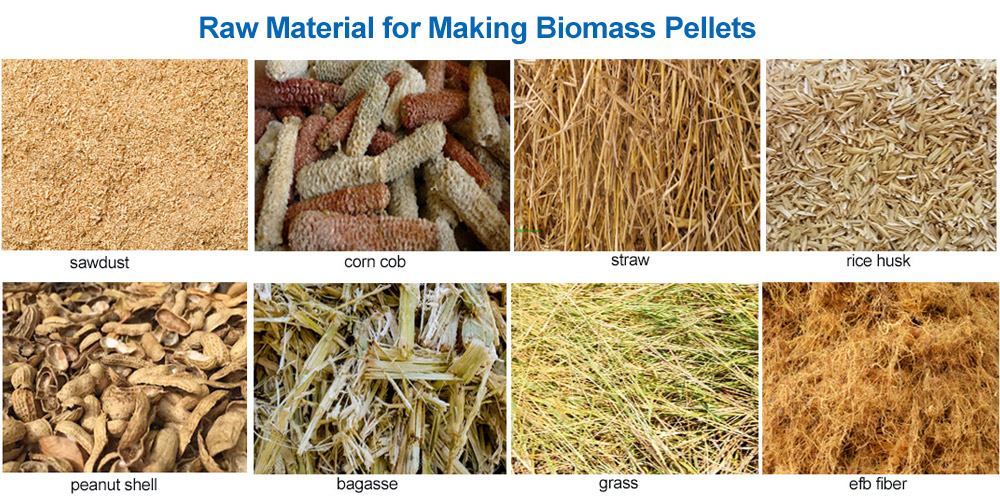

The raw materials of biomass pellets mainly include sawdust, straw, agricultural waste and other wastes.

Sawdust. Derived from wood processing, furniture manufacturing waste, etc., it has the characteristics of low moisture content and easy transportation and storage.

Straw. Including rice straw, wheat straw and he harvested stems and leaves of crops etc.

Agricultural waste. Such as potato peels, corn peels, etc.

Other waste. Including municipal garbage, industrial waste, etc.

Specific materials. Combustible materials such as shavings, sawdust, wood chips, peanut shells, rice husks, bamboo chips, palm, caragana, medicinal residues, fungus residues, waste cloth, etc. can be used as raw materials for biomass pellet machines.

These materials are rich in cellulose, hemicellulose and lignin and are ideal raw materials for making biomass pellets.

The main components of biomass materials are the following: lignin; cellulose; sugar content; oil content

Lignin: The characteristics is large specific gravity and with certain viscosity, but the release of viscosity is conditional. This condition is exactly the material requirement of our pellet machine. If the viscosity release condition is met, the molding will be better.

Cellulose: Small specific gravity (relatively light), fibrous, biomass materials can be pressed into pellets, cellulose is also an essential component

Sugar content: Non-flammable organic matter. If the sugar content is large, it will easily cause the particles to coke/sludge.

Oil content: non-flammable organic matter, such as oil palm and palm shells, with high oil content

The forming principle of biomass pellets:

For biomass type materials, the cellulose components overlap with each other and the lignin releases viscosity. The wood pellet machine pressure roller gives external force to squeeze. At the same time, the friction of the die hole wall blocks the advancement of the material. Under the action of the two-way extrusion force, biomass pellets are finally formed ( The sugar/oil content also helps to suppress the pellets. They are all sticky and do not need to be released. They come with their own conditions). Therefore, the biomass pellet machine does not require additives to make pellets.

Biomass pellet production line process flow:

Production process: crushing section - grinding section - drying section - pelleting section - cooling section - packaging section

Production equipment: Main equipment includes: wood crusher, wood chipper, hammer mill, rotary screener, mixer, rotary dryer, wood pellet machine, dust collector, cooler, vibrating screener, packaging machine, etc.

Auxiliary equipment: conveyor, iron remover, raw material warehouse, finished pellets silo.

We have more than 10 years of production, design, and installation experience. Feedback from tens of thousands of domestic and foreign customers is the basis and guarantee for our process design. We will customize a scientific and reasonable production process for you based on your materials, output, factory space and other factors. Contact us to customize your wood pellet plant.

20t/h Wood Pellet Production Line in Indonesia

20t/h Wood Pellet Production Line in Indonesia

Country: Indonesia

Capacity: 20t/h

Raw Material: subtropical trees

10t/h Wood Pellet Production Line in Malaysia

10t/h Wood Pellet Production Line in Malaysia

Country: Malaysia

Capacity: 10t/h

Raw Material: wood log (acacia wood, eucalyptus wood)

10t/h Wood Pellet Production Line in Philippines

10t/h Wood Pellet Production Line in Philippines

Country: Philippines

Capacity: 10t/h

Raw Material: wood log

6t/h Wood Pellet Production Line in Thailand

6t/h Wood Pellet Production Line in Thailand

Country: Thailand

Capacity: 6t/h

Raw Material: wood log