Evaporation Capacity: 0.8-4t/h

Moisture content after drying: 12-15%

Rotating Spped: 5-10r/min

Gradient: 3-5°

The three-cylinder rotary dryer is composed of three cylinders. the material is swirled through three cylinders to fully utilize the heat to dry the material to the specified moisture requirements.

Equipment Principle: The material enters the inner layer of the rotary drum from the feeding device to achieve downstream drying. The material is continuously picked up and scattered under the lifting plate in the inner layer to realize heat exchange in a spiral manner. The material moves to the other end of the inner layer and enters the middle layer for countercurrent drying. The material is continuously pushed forward in the middle layer in a two-step forward and one-step back motion. The material in the middle layer fully absorbs the heat emitted by the inner drum, but also the heat of the middle drum, while prolonging the drying time, achieving the optimal drying state of the material.

The material travels to the other end of the middle layer and falls into the outer layer. The material movess in a rectangular multi-loop manner in the outer drum. The material that reached the drying effect travels quickly and is discharged from the drum under the action of hot air. The wet material that not reached the drying effect cannot be quickly moved due to its own weight. the materials are fully dried in this rectangular lifting plate to achieve the drying purpose.

| Model | Power(kw) | Evaporation Capacity(t/h) | Inner Temperature | Outlet Temperature |

| YGHGφ1.8*10*3 | 2.2x4+37+3+3+2.2 | 0.8-1.4 | 300-500℃ | 90-100℃ |

| YGHGφ2.2*10*3 | 3x4+55+5.5+5.5+3 | 1.2-2.2 | ||

| YGHGφ2.5*10*3 | 5.5x4+75+5.5+5.5+3 | 2-3 | ||

| YGHGφ3.0*10*3 | 5.5x4+90+5.5+5.5+3 | 2.8-4 |

1. High thermal efficiency. Three-cylinder design, high contact surface between materials and hot air, high thermal efficiency utilization, large production capacity.

2. Three-cylinder structure, compact layout, saving space.

3.The design of the lifting plate in the cylinder is multi-angle, Low energy consumption, saving drying cost.

4. Suitable for large-scale drying production lines such as sawdust and powdder materials.

5. Intelligent PLC control system, saving labor.

6. The cylinders of the three-cylinder dryer are fixed by ROTEXMASTER independent research and development of patented technology, which can prevent welding deformation caused by thermal expansion and contraction.

7. Integral spiral rigid structure, won't deform under long-term high temperature.

8. Compliance with various dust and emission regulations.

Three cylinder sawdust rotary dryer applies for a variety of powder materials, such as sawdust, powder, rice husk, wood shavings, etc.

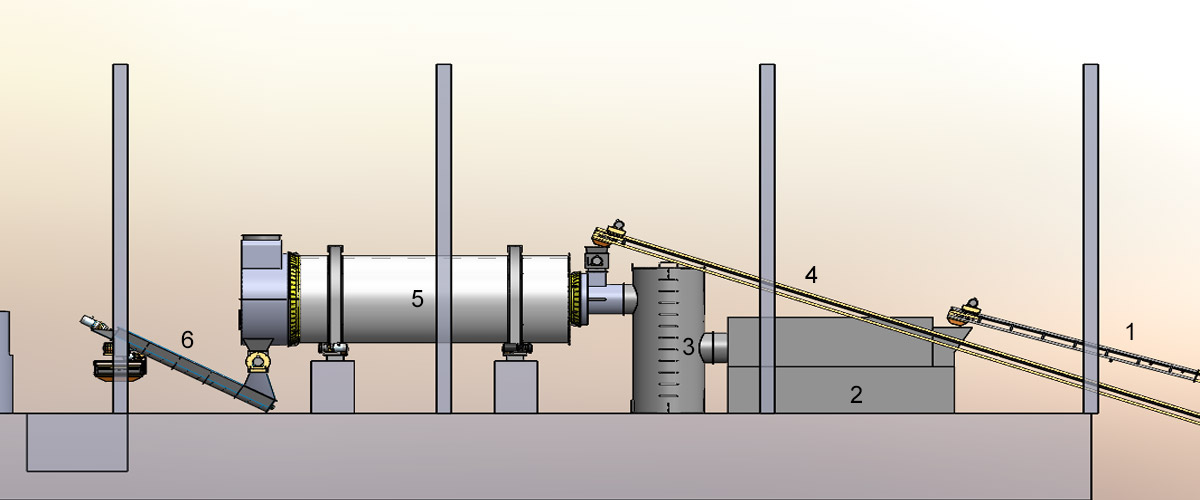

1. Feeding Conveyor for Stove 2. Chain Stove 3. Chamber 4. Feeding Conveyor for Dryer 5. Biomass Dryer 6. Discharging Conveyor

Q: Are you manufacturer or trading company?

Q: I am newer to biomass industry, how to design suitable pellet plant?

Q: How to prepare for setting up a wood pellet production line?

Q: How can you guarantee the after-sales service?

Q: Are there some machines in my area I can observe?

Q: What type of raw materials can be pelletized by RotexMaster pellet machine?

Q: How to confirm the compression ratio of mould for my raw material?

Q: What is the main process for making biomass pellets?

Q: What is your work flow if we order Rotexmaster equipment?

For all inquiries fill in the form below to send us a brief message,and we will get back to you as soon as possible.