Comparison between Three-Phase Asynchronous Motors and Permanent Magnet Motors

The energy efficiency advantages of permanent magnet motors are often highlighted by comparing them to three-phase asynchronous motors with lower energy efficiency ratings. However, with current technology, when compared to three-phase asynchronous motors meeting the new national standard's Level 1 energy efficiency rating, the efficiency advantage of permanent magnet motors is not significant, only improving by 2%.

Energy Efficiency Performance Under Full-Load Conditions

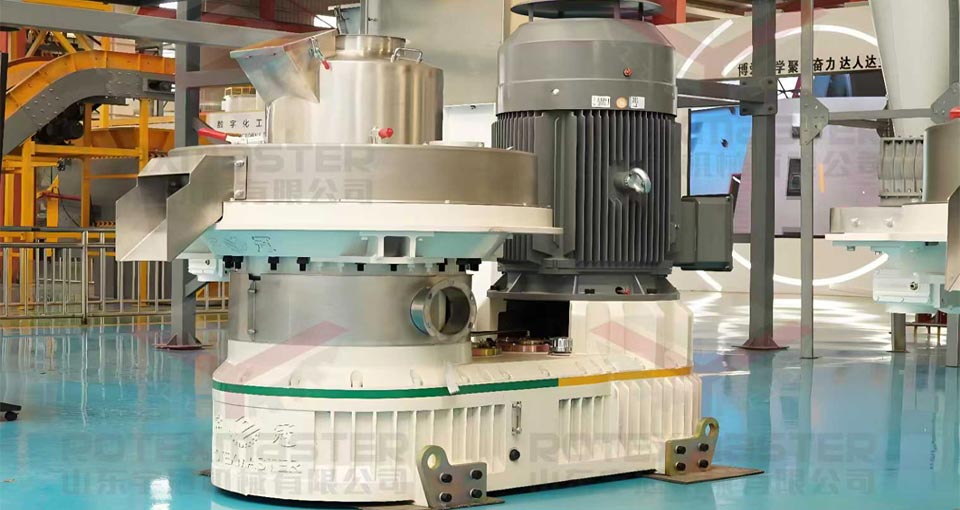

The pellet machine's main motor typically operates at full load. With current technology, the energy efficiency performance of permanent magnet motors and three-phase asynchronous motors in this application scenario is comparable. Therefore, the energy efficiency advantage of permanent magnet motors under full-load conditions is not significant.

Permanent Magnet Motor Power and Output

In the pelletizing industry, manufacturers often pursue high production output at a constant cost to increase profitability. Most manufacturers generally believe that permanent magnet motors are the ideal choice for the same power output, due to their higher production output and smaller design compared to three-phase asynchronous motors. However, this is not the case. For example, while both rated at 280 kW and seemingly identical dimensions, a permanent magnet motor can actually operate at 400 kW. Therefore, increased production output is not surprising and, to some extent, explains its high output. However, actual costs are calculated based on actual energy consumption, so there is no reduction in cost. Furthermore, the output torque of a 400 kW permanent magnet motor exceeds the design capacity of the wood pellet machine's reducer, significantly shortening the reducer's lifespan and posing a significant safety risk.

Magnetic Degradation and the Impact of High Temperature

Under current technology, the permanent magnet material in permanent magnet motors naturally degrades over time, at a rate of at least 3% per year. High-temperature operation significantly accelerates this process, impacting the motor's long-term performance and energy efficiency. In high-power applications, a water cooling system is essential to maintain effective motor cooling. However, this system places high demands on water quality to prevent corrosion and scale formation.

Cost Considerations

Currently, the combined cost of a permanent magnet motor and the selected dedicated inverter is typically more than double that of a traditional motor, which needs to be considered when making investment decisions.

Overspeed Capacity Limitations

Under current technology, ordinary three-phase asynchronous variable-frequency motors can achieve up to double their speed and maintain long-term operation through inverter speed regulation. However, permanent magnet motors can only overspeed by a maximum of 10%. Any higher overspeed increases current and reduces energy efficiency. These overspeed limitations may affect their flexibility in certain application scenarios.

In summary, when choosing a motor, you need to comprehensively consider the operating conditions, long-term equipment performance, cost, and maintenance. In the current scenario of a biomass pellet machine operating at full load, three-phase asynchronous motors may still be the better choice due to their stable energy efficiency and cost-effectiveness. Of course, technology is always advancing. If permanent magnet motors can achieve further breakthroughs in efficiency, cooling, and cost, the future is worth looking forward to. I hope this article can help you gain a more comprehensive perspective and make the most appropriate technology choice for your needs!

Analysis of the market prospects of biomass pellets in Myanmar

20t/h Wood Pellet Production Line in Indonesia

20t/h Wood Pellet Production Line in Indonesia

Country: Indonesia

Capacity: 20t/h

Raw Material: subtropical trees

10t/h Wood Pellet Production Line in Malaysia

10t/h Wood Pellet Production Line in Malaysia

Country: Malaysia

Capacity: 10t/h

Raw Material: wood log (acacia wood, eucalyptus wood)

10t/h Wood Pellet Production Line in Philippines

10t/h Wood Pellet Production Line in Philippines

Country: Philippines

Capacity: 10t/h

Raw Material: wood log

6t/h Wood Pellet Production Line in Thailand

6t/h Wood Pellet Production Line in Thailand

Country: Thailand

Capacity: 6t/h

Raw Material: wood log