In the context of global energy transformation and environmental sustainable development, Cambodia is accelerating its energy transformation, and biomass pellets, as a clean and renewable fuel, are experiencing explosive growth. The Cambodian government plans to increase the proportion of clean energy to 70% by 2030, and promises to achieve carbon neutrality by 2050. The installed capacity of biomass power generation will increase from the current 27 megawatts to 98 megawatts in 2030 (an increase of 263%). This policy dividend has created huge space for the biomass pellet market.

1. Policy dividends: a strategic fulcrum for national energy transformation

Cambodia has built a clear clean energy roadmap:

Stop building new coal-fired power projects: Starting from 2024, coal-fired power investment will be completely terminated and renewable energy will be turned to;

Biomass special plan: According to the "2022-2040 Power Development Master Plan", the installed capacity of biomass power generation will reach 198 megawatts in 2040, an increase of more than 6 times compared with the current level;

Funding and tax incentives: Establish a biomass power generation fund and provide tax exemptions, preferential loans and other support for projects.

From 2024 to 2029, Cambodia has approved 23 power investment projects (including 1 biomass-solar joint project) with a total investment of US$5.79 billion, covering many provinces across the country.

2. Resource endowment: an underdeveloped treasure trove of raw materials

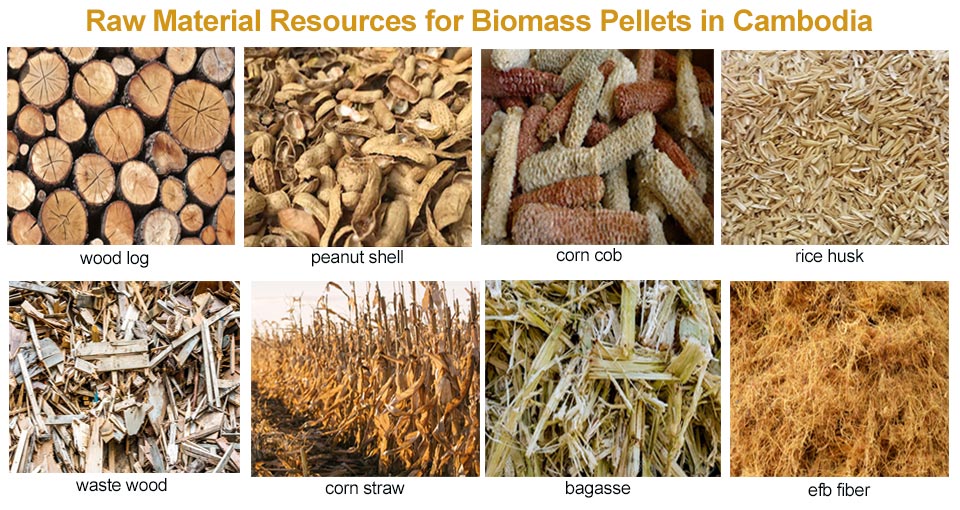

Cambodia has a wide forest coverage rate, with a large amount of forest resources and a large amount of agricultural waste, but the utilization rate is less than 15%. The main raw materials include:

Rice husks and corn stalks: accounting for 40% of the total agricultural waste, with a calorific value of about 3000 kcal/kg;

Sugarcane bagasse: the annual output of sugar mill concentration areas (such as Preah Vihear Province) exceeds 500,000 tons, and China's aerospace energy-saving project has achieved an annual processing of 480,000 tons of bagasse to generate 130 million kilowatt-hours of electricity;

Wood chips and empty palm fruit bunches: The proportion of residues in forestry processing areas accounts for 30%.

Distribution and characteristics of main biomass raw materials in Cambodia

| Raw material type | Annual production estimate | Main distribution areas |

| Rice Husk | 2 million tons+ | Mekong Plain |

| Bagasse | 500,000 tons+ | Preah Vihear, Kampong Cham Province |

| Wood | 300,000 tons+ | Koh Kong Province, Mondulkiri |

3. Obvious economic cost advantage

Compared with traditional fossil energy, the production cost of biomass pellets is relatively low. Its raw materials mainly come from agricultural and forestry waste, which is not expensive to obtain and is renewable and sustainable. In addition, Cambodia's low labor costs further reduce the production cost of biomass pellets, making them more price competitive in the market and providing consumers with an affordable energy option.

4. Application scenarios: Diversified penetration from electricity to industry

Power generation:

Biomass pellets are used for co-firing in power plants to replace imported coal. Currently, biomass power generation accounts for only 0.6% (49MW) of the country's installed capacity, but it is planned to increase to 98MW in 2030;

The government promotes the "biomass-solar" hybrid project to solve the problem of photovoltaic interruption at night.

Industrial boiler fuel:

Building materials, food processing and other companies are accelerating their transformation. For example, in 2023, a Cambodian building materials company introduced a 6-ton biomass steam boiler, reducing fuel costs by 40%;

Sugar mills, rice mills, etc. use their own waste to achieve energy self-sufficiency, forming a closed loop of circular economy.

5. Challenges and bottlenecks: infrastructure and technological shortcomings

Despite the huge potential, the market still faces three constraints:

The raw material collection system is scattered: there is a lack of a large-scale collection network, and transportation costs account for more than 35% of the total cost of pellets;

Local technology is weak: reliance on imported equipment and a shortage of operation and maintenance personnel have led to delays in project commissioning;

Lack of cost competitiveness: The cost of biomass power generation is about US$0.12/kWh, which is higher than the US$0.08/kWh of coal-fired power generation, and policy subsidies are required to maintain it.

Conclusion: Strategic action suggestions for seizing the window period

The Cambodian biomass pellet market is at the intersection of policy dividends and demand explosion: by 2030, the power generation sector alone will create a 70,000-ton/year pellet demand gap. It is recommended that enterprises focus on the following areas:

Power generation project support: lock in biomass hybrid projects in 23 new power stations;

Agricultural processing clusters: build pellet production lines with sugar mills (such as Preah Vihear) and rice mills;

Industrial boiler transformation: target high-energy-consuming enterprises such as building materials and food, and provide "equipment + fuel" bundled solutions.

The gears of green transformation are already turning in Cambodia - when the clock for the exit of fossil energy rings, companies with technology and capital will become the real winners of the clean energy revolution in this tropical fertile land.

As professional manufacturer of biomass pellet production line, we have abundant experience, can customize suitable biomass pellet plant according to customer's different raw material, and capacity requirement.

Analysis of the market prospects of biomass pellets in Myanmar

20t/h Wood Pellet Production Line in Indonesia

20t/h Wood Pellet Production Line in Indonesia

Country: Indonesia

Capacity: 20t/h

Raw Material: subtropical trees

10t/h Wood Pellet Production Line in Malaysia

10t/h Wood Pellet Production Line in Malaysia

Country: Malaysia

Capacity: 10t/h

Raw Material: wood log (acacia wood, eucalyptus wood)

10t/h Wood Pellet Production Line in Philippines

10t/h Wood Pellet Production Line in Philippines

Country: Philippines

Capacity: 10t/h

Raw Material: wood log

6t/h Wood Pellet Production Line in Thailand

6t/h Wood Pellet Production Line in Thailand

Country: Thailand

Capacity: 6t/h

Raw Material: wood log